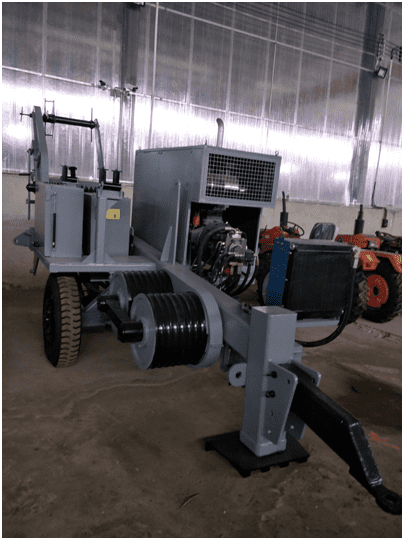

Stringing Equipment hydraulic cable puller

Payment Term: T/T, L/C

Incoterm: FCA, FOB, CFR, CIF

MOQ: 1 unit

Productivity: 50 units per month

Transportation: Ocean, Land, Air

Packaging: Plastic Bag or Belt

Place of Origin: CHINA

Certificate: By China High Voltage Institute.

Delivery Time: 5-10 days

Warranty: 1 year since B/L date

Product Status: In stock for 5units each type, max 3-4 weeks required if for more mass production.

View More Hydraulic Pullers & Tensioners From QYPOWERLINE

Stringing Equipment hydraulic cable puller

Stringing Equipment hydraulic cable puller is used for pulling and releasing traction rope, optical cable, conductor, and tower assembly in mountainous areas and plains. The machine is portable, combined, and detachable for handling. It is ideal traction equipment for power line transmission construction in mountainous areas. These cable puller tensioners are also used for traction on railway trunk electric locomotives, industrial and mining electric locomotives, electric/diesel locomotives, and various electric vehicles (such as battery cars, urban trams, and Metro electric vehicles). It can be divided into a single-cylinder diesel puller and a four-cylinder diesel puller.

Product features: the pulling force and pulling speed is steplessly adjustable, intuitive display. The large traction force can be preset, and the overload is automatically protected. The pressure loss automatic braking function ensures operation safety when the engine suddenly stalls or the hydraulic system loses pressure due to other reasons. It is equipped with a hydraulic traction rope installation device to facilitate the replacement of a steel wire rope drum. With an automatic winding device for steel wire rope, It is automatic for rope arrangement, and convenient for loading and unloading.

Description:

A. Stringing Equipment Hydraulic Pullers are widely used for stringing the conductors & cables(OPGW, ADSS, 500kv traction rope, ACSR series, etc.) in the overhead power line stringing construction.

B. This hydraulic puller has a set of tension early warning systems, which can automatically adjust the speed according to the undue load or friction produced on the line and can keep the tension at the set value.

C. Tension or pulling force can be preset, spring-applied brake, reliable overhead protection mechanism, easy to operate.

Main configurations:

Engine: CUMMINS made by a joint venture in China

Main hydraulic motor: REXROTH in German

Main hydraulic pump: REXROTH in German

Speed Reducer: REXROTH in German

Hydraulic valve (Italy ATOS); pipeline system and meter (made in Italy or German WIKA)

Technical Parameters:

Product No. | Model | Max pulling force (KN) | Max Continuous pulling force (KN) | Corresponding speed (km/h) | Max continuous pulling speed (km/h) | Puller wheel diameter Dia.Φ(mm) | Groove number | Max steel wire rope Dia.Φ(mm) | Max steel reel Dia. Φ(mm) | Engine Power (KW/RPM) | Electrical System | Dimensions (mm) | Weight(kg) |

10552 | QYT280KN | 280 | 250 | 2.5 | 5 | 960 | 11 | 38 | 1600 | 298/2100 (Cummins) | 24 | 5800×2500×2850 | 12800 |

10553 | QYT180KN | 180 | 150 | 2.5 | 5 | 700 | 10 | 27 | 1400 | 220/2200 (Cummins) | 24 | 4300×2360×2380 | 6800 |

10554 | QYT90KN | 90 | 80 | 2.5 | 5 | 540 | 8 | 21 | 1600 | 118/2500 (Cummins) | 24 | 4000*2200*2100 | 4000 |

10555 | QYT60KN | 60 | 50 | 2.5 | 5 | 450 | 7 | 18 | 1400 | 77/2800 (Cummins) | 24 | 3800×2100×2300 | 3500 |

10556 | QYT40KN | 40 | 35 | 2.5 | 5 | 450 | 7 | 16 | 1400 | 77/2800 (Cummins) | 24 | 3800×2100×2300 | 3500 |

10557 | QYT30KN | 30 | 25 | 2.5 | 5 | 300 | 7 | 13 | 1400 | 38/2200(Deutz air-cooled engine) | 24 | 3200x1600x2000 | 1500 |