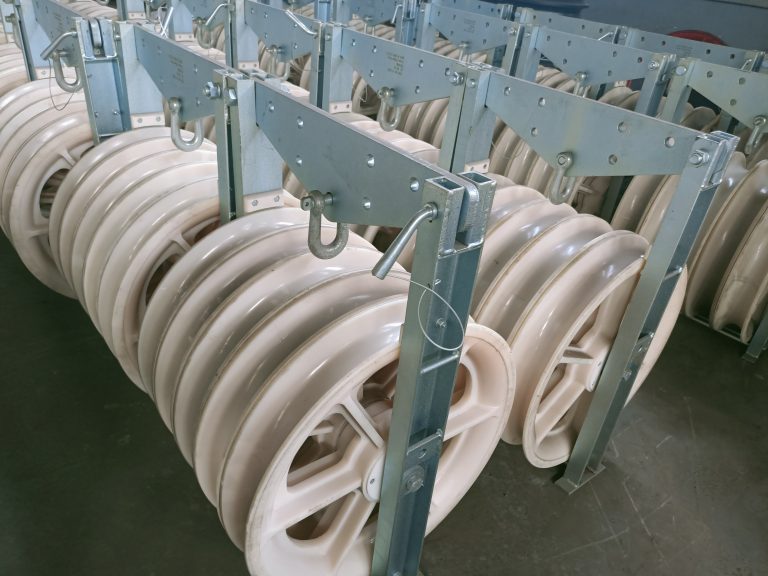

Safety Guidelines for Using 3-Sheave Wire Stringing Blocks in Power Line Projects

3-sheave wire stringing blocks are commonly used in power transmission line projects to help guide…

3-sheave wire stringing blocks are commonly used in power transmission line projects to help guide and support the conductor during the installation process. These blocks feature three pulleys or sheaves that are designed to reduce the friction and tension on the conductor, ensuring that it is properly positioned and supported. However, using 3-sheave wire stringing blocks requires careful attention to safety, as the blocks are subject to significant tension and stress during use. In this blog, we will discuss some important safety guidelines for using 3-sheave wire stringing blocks in power line projects.

- Proper Inspection

Before using 3-sheave wire stringing blocks, it is essential to inspect them carefully to ensure that they are in good condition and free from defects. Check for signs of wear or damage, such as cracks or dents, and make sure that all of the parts are securely fastened and in good working order. Do not use any blocks that appear to be damaged or worn, as this can compromise the safety and effectiveness of the stringing process.

- Load Capacity

It is essential to choose 3-sheave wire stringing blocks that are rated for the weight of the conductor and any other equipment that will be used during the installation process. The load capacity of the blocks should be carefully considered, and the blocks should never be overloaded or used to support more weight than they are designed to handle. Using blocks that are not rated for the weight of the conductor can cause them to break or become damaged, leading to potential safety hazards.

- Proper Installation

When installing 3-sheave wire stringing blocks, it is important to follow proper installation procedures to ensure that they are securely fastened and positioned correctly. Use the appropriate tools and equipment to install the blocks, and make sure that they are aligned properly to prevent the conductor from becoming snagged or damaged. Additionally, make sure that the blocks are properly tensioned to ensure that they function as intended during the stringing process.

- Proper Use

During use, it is important to monitor the tension on the conductor and the blocks carefully to prevent overloading or other safety hazards. The tension should be monitored throughout the stringing process, and the blocks should be adjusted as needed to ensure that they are functioning properly. Additionally, make sure that the blocks are positioned correctly and that the conductor is properly supported at all times.

- Regular Maintenance

Finally, it is important to regularly inspect and maintain 3-sheave wire stringing blocks to ensure that they remain in good working order. Regular inspections can help to identify any signs of wear or damage before they become safety hazards, and regular maintenance can help to keep the blocks functioning properly over the long term.

In conclusion, using 3-sheave wire stringing blocks in power line projects requires careful attention to safety. By following proper inspection, load capacity, installation, use, and maintenance procedures, power grid operators can ensure that the blocks function properly and safely during the installation process. This can help to prevent accidents and injuries, while also ensuring the safe and efficient operation of the power grid over the long term.